Total Production Management platform

DIGITALISING SMART FACTORIES

With AIDA software suite, you will get the ideal framework for digitalisation of your production.

Whether you want to connect your old machines, or integrate new modern one, AIDA has all prerequisites to integrate all of them, gather data from machines, send some data to machines, monitor all production, materials, semi-finished products, warehouses – you are getting true Total Production management.

INDUSTRY 4.0

A combination of cyber-physical systems, the Internet of Things and the Internet of Systems make Industry 4.0 possible and the smart factory a reality. As a result of the support of smart machines that keep getting smarter as they get access to more data, our factories will become more efficient and productive and less wasteful. Ultimately, it's the network of these machines that are digitally connected with one another and create and share information that results in the true power of Industry 4.0. – This is exactly what AIDA is doing at your factory!

SCALABLE

AIDA software suite today runs SME production lines and big factories with many different production lines. One of the main strengths of AIDA is its scalability, so whether you are small, medium or large production company you will always get the best of all worlds. You will always get the same reliable framework, and you can decide what modules you need for your business. When your business grows, it is easy to upgrade your system with additional modules and new functionalities which will be tailored for you.

UNLOCK THE FULL POTENTIAL OF YOUR PRODUCTION

Data is the driver of business processes, and when harnessed properly, it can boost organizations in unseen ways and even render outdated business models obsolete. The ability to harness its power is today’s great differentiator. But with so much data at our disposal, putting it to action is an art form in itself. With AIDA software suite, and its modules you will be able to use all the dana from your production floor at the best, and boost your future production and processes.

VARIOUS ERP INTEGRATION

AIDA software suite is focused on vertical and horizontal integration on your production floor. On the top AIDA can integrate with almost every ERP system, and when you add that with unlimited options of connectivity with machines, sensors, etc. In the end, you have one well connected and integrated robust production system on which you can rely on.

REVEAL YOUR HIDDEN FACTORY

Many manufacturers may desire to increase throughput and revenues, but are hesitant to invest in new equipment, expand their factory footprint or add a second shift. The best solution is to release the untapped capacity held within the hidden factory.

With AIDA software suite you will have access and real time view in all processes in your production, and when you combine it with all the dana which is gathered in real time, you will be able to identify all bottlenecks, loses, wasteful operations, and in the end make changes that will increase your productivity and generate additional revenue.

Features

Application Industries and Success Stories

Tobacco Industry

Aerospace Industry

Automotive Industry

Food Industry

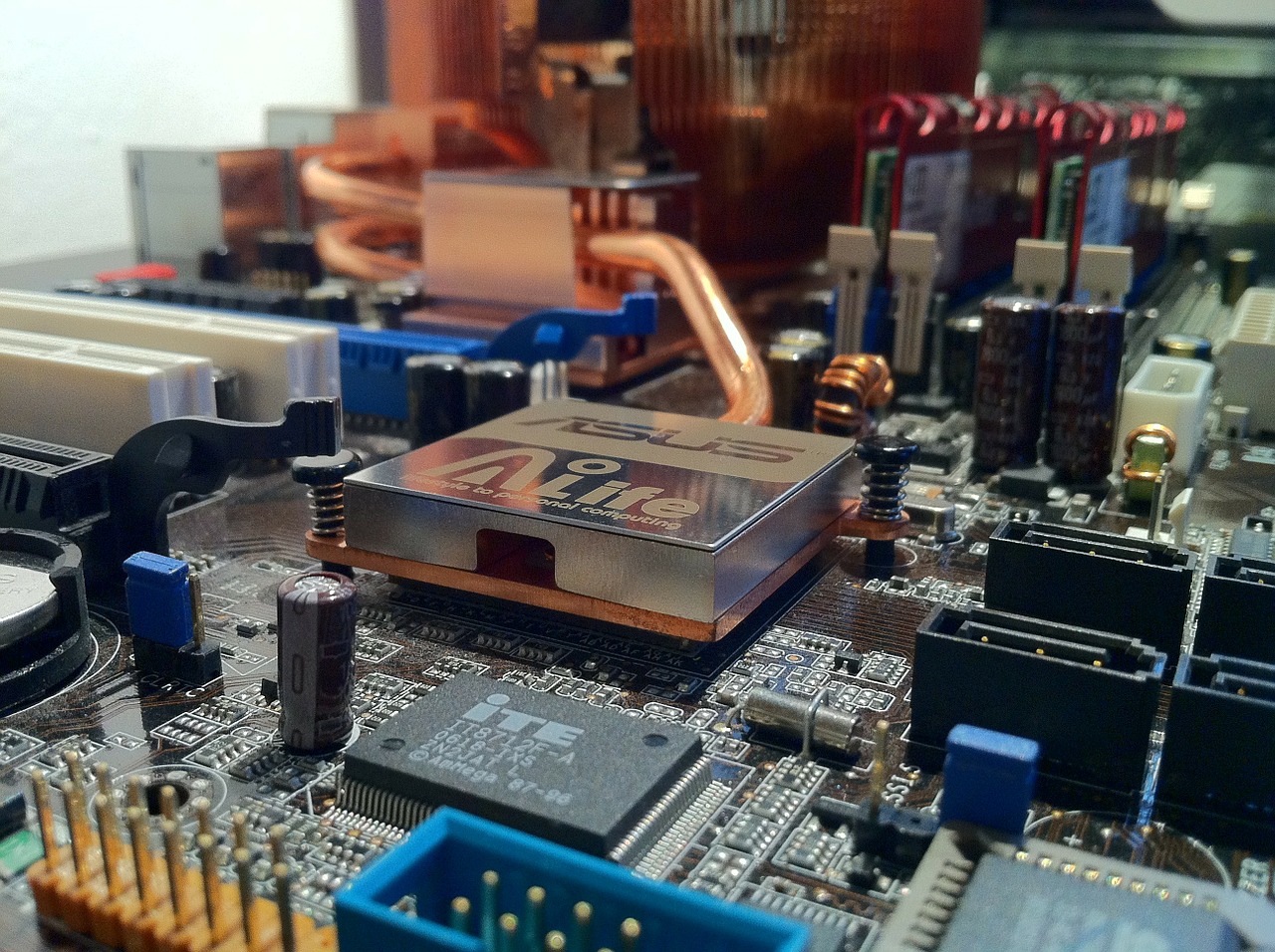

Electronic Industry

GOT A QUESTION?

We’re here to help and answer any question you might have. We look forward to hearing from you.